rockwell hardness test measures hardness based on|rockwell hardness tester least count : suppliers Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined . The manual ( link to screenshot of relevant part on page 8) states the following: 1st M.2 .

{plog:ftitle_list}

Resultado da 30 dez 2023, 12:50. opinião. Agostinho Costa. "A Ucrânia não poderá queixar-se muito" do apoio do Ocidente, diz Agostinho Costa. 27 dez .

The Rockwell test is based on measurement of the depth of penetration with the hardness number read directly from the dial gauge or digital display that is part of every tester. In .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined .Rockwell hardness test measures the permanent depth of indentation on a metal by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. . The Rockwell scale is selected based on . In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm .

The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article. + 86 755 61301520 . you need to understand some basic measurement units in this case. In the Rockwell hardness testing, the .

The hardness value is then calculated based on the applied load and the surface area of the impression. This method is commonly used when large grains or coarse microstructures are present in the material. . Rockwell Hardness Test. The Rockwell hardness test measures the depth of penetration of an indenter under a large force (major load .

The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine knives. How Rockwell Hardness Gets Measured.The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the .

Load: The Rockwell hardness test uses a pre-load of 10 kgf, followed by the application of the main load, which varies depending on the Rockwell scale being used (e.g., 60 kgf for the Rockwell A scale, 150 kgf for the Rockwell C scale). The load is applied for a . The Leeb Hardness Test, also known as the rebound hardness test, measures hardness by analyzing the rebound of an indenter, rather than the size of an indentation. It is portable and ideal for on-site testing of large and heavy components, offering a non-destructive method that causes minimal damage to finished parts and coatings. The RockGen Rockwell Hardness Testing System was designed to test the hardness level of metal based on the indentation they leave on a tested material according to the Rockwell scale. The machine is capable of measuring the resolution of a material to a 0.001″.

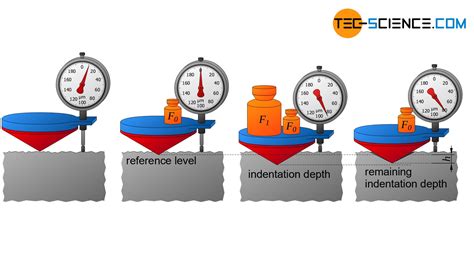

Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.The Rockwell hardness test is a non-destructive testing method that is used to measure the hardness of materials. . The Rockwell Hardness Test is one of several tests used to determine whether a material is solid and durable enough to be employed as a component of an object. . Rockwell hardness test helps select materials based on hardness .In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as .

The Rockwell hardness test measures hardness in progressive numbers on different scales corresponding to the size of ball indentor used; scale symbols correspond to the loads of 60 and 150 kg. Creep and elastic recovery factors are involved in determining the Rockwell hardness. . (ASTM D 674). The Durometer test method is based on the .A Rockwell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and that measures Rockwell hardness by the Rockwell indentation hardness test principle. Rockwell .

The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard carbon steels.

Rockwell testers measure hardness based on the depth of penetration of an indenter into the surface of a material under a known load. Superficial Rockwell is used when the material being tested is relatively thin .

What is The Rockwell Hardness Test? Rockwell hardness testing is measured using the Rockwell hardness scale with the method defined in ASTM E18 and BS EN ISO 6508-1. Rockwell hardness testing is performed with an indenter of a specified size applied with a specified force for a fixed amount of time.The Rockwell hardness test is an essential tool in material science, offering a fast and trustworthy way to measure how hard materials are, with a special focus on metals. . Choose the appropriate Rockwell scale on the tester based on the material. Apply the initial force (preload) to ensure the indenter is properly seated. .

presence of mdl impacts factors test

The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied. Hardness numbers have no units and are commonly given in the R, L, M, E and K scales. . (Durometer) test or Rockwell hardness test. Both methods measure the resistance of the plastic toward indentation. Both scales .Rockwell hardness test is one of the most common indentation hardness tests developed for hardness testing. In contrast to the Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). . The traditional methods are based on .

The Rockwell test is described in ASTM E18 – 20 (Standard Test Methods for Rockwell Hardness of Metallic Materials). Vickers Hardness Test The Vickers hardness test involves the use a 4-sided square-based pyramid indenter, with a precisely defined constant force on the test specimen to evaluate the surface area of the indentation.The Rockwell hardness test is a measure of a material's resistance to indentation. It involves applying a minor preliminary load, followed by a major load through an indenter, usually a diamond or tungsten carbide ball. . Industries involved in manufacturing plastic components, packaging materials, and polymer-based products utilize Rockwell .1. Testing Principle. The Rockwell hardness test measures hardness based on the depth of penetration of an indenter under a specific load. It utilizes two types of indenters: a diamond cone for harder materials and a steel ball for softer materials. The Rockwell hardness test. Rockwell is a fast hardness test method developed for production control, with a direct readout, mainly used for metallic materials. The Rockwell hardness (HR) is calculated by measuring the depth of an indent after an indenter has been forced into the specimen material at a given load.

Minimum Thicknesses for the Rockwell Hardness Test. Since the Rockwell test needs to make an indent in the test piece, there’s a minimum thickness associated with the test. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Here’s a little chart on the minimum material .The Rockwell M hardness test is used to measure the hardness of a wide range of materials. For example, metals, plastics, ceramics, and composite materials (such as fiberglass and carbon fiber). . Part of the data and information contained in the Polymer Selector are genericised based on commercial literature provided by polymer suppliers and .

rockwell hardness testing method

pressure film impact testing

pressure vessel impact testing

price of a gardener impact tester

principle of charpy impact test

web18 de jan. de 2024 · Primeira partida do Vasco no Campeonato Carioca 2024 acontece hoje (18) contra o Boavista com transmissão ao vivo via streaming; a seguir, veja como .

rockwell hardness test measures hardness based on|rockwell hardness tester least count